What distinguishes bar grates from other types of mechanical treatment equipment?

Back Raked Screen are the most optimal and reliable equipment for the extraction of large and medium-sized contaminants from treated water.

The improved hydraulic characteristics compared to other types of grids and the cleaning principle of the filter cloth allow for the removal of large and medium-sized impurities from the treated water.

and the cleaning principle of the filter cloth allow the widest range of contaminants to be handled without stoppages or jams.

The technical features of the grating make it one of the most effective solutions for use in water intake structures and reclamation pumping stations.

Original technical solutions:

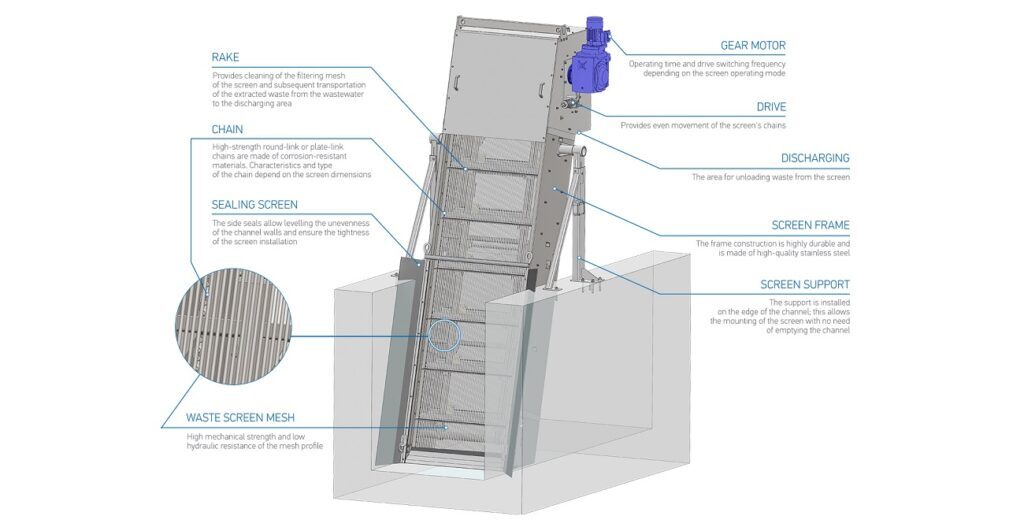

- The main distinctive feature and main advantage of the bar grating is that the rake mechanism is located behind the filter cloth and is in contact with already treated water. This significantly reduces the likelihood of fouling or jamming by large objects.

- The web is a set of individual bars bent at the top towards the discharge side and fixed only at the bottom of the screen. This makes it possible to treat water with fibrous inclusions that tend to coil on the grate elements. Pollutants are moved along the bars by a rake mechanism and are easily discharged from the free ends of the filter bars.

- The rods of the filter cloth are installed along the entire length of the grid - from the bottom of the channel to the discharge. This facilitates the removal of the rejects and reduces the possibility of their return back into the channel on the way of transportation.

- The round profile of the bars reduces hydraulic resistance in comparison with rectangular bars and ensures high throughput capacity of the grid.

- Under water there are no rotating elements of the grating (bearings, rollers, shafts, etc. ) The tines have support pads with plastic pads, which slide on the guide elements of the frame. As a result, there are no maintenance and replacement elements in the channel part of the grating.

- The bar grating is highly resistant to abrasives (sand).

- The rake spacing is 0.5m, which guarantees timely removal of dirt from the web and ensures high efficiency during peak water and dirt inflow periods.

- Grate drive: high reliability worm gear motor from one of the world leaders NORD Drive Systems.

Simplicity and ease of operation:

- There are no complicated mechanisms and components in the design that require constant attention and maintenance.

- The grids do not stop when large amounts of debris enter. Congestion does not form in the ducts.

- Sliding plastic pads on the tine support pads are easily changed over the channel in the accessible part of the grate.

- The use of round link traction chains makes it convenient and cheap to maintain and repair.

- The grids are easy to maintain due to the accessibility of the main components and drive.

- The equipment is equipped with a control system operating in various modes.

- It is possible to synchronize the complex with other types of equipment, such as a squeezing press or conveyor.

- Easy installation and quick commissioning of the equipment.

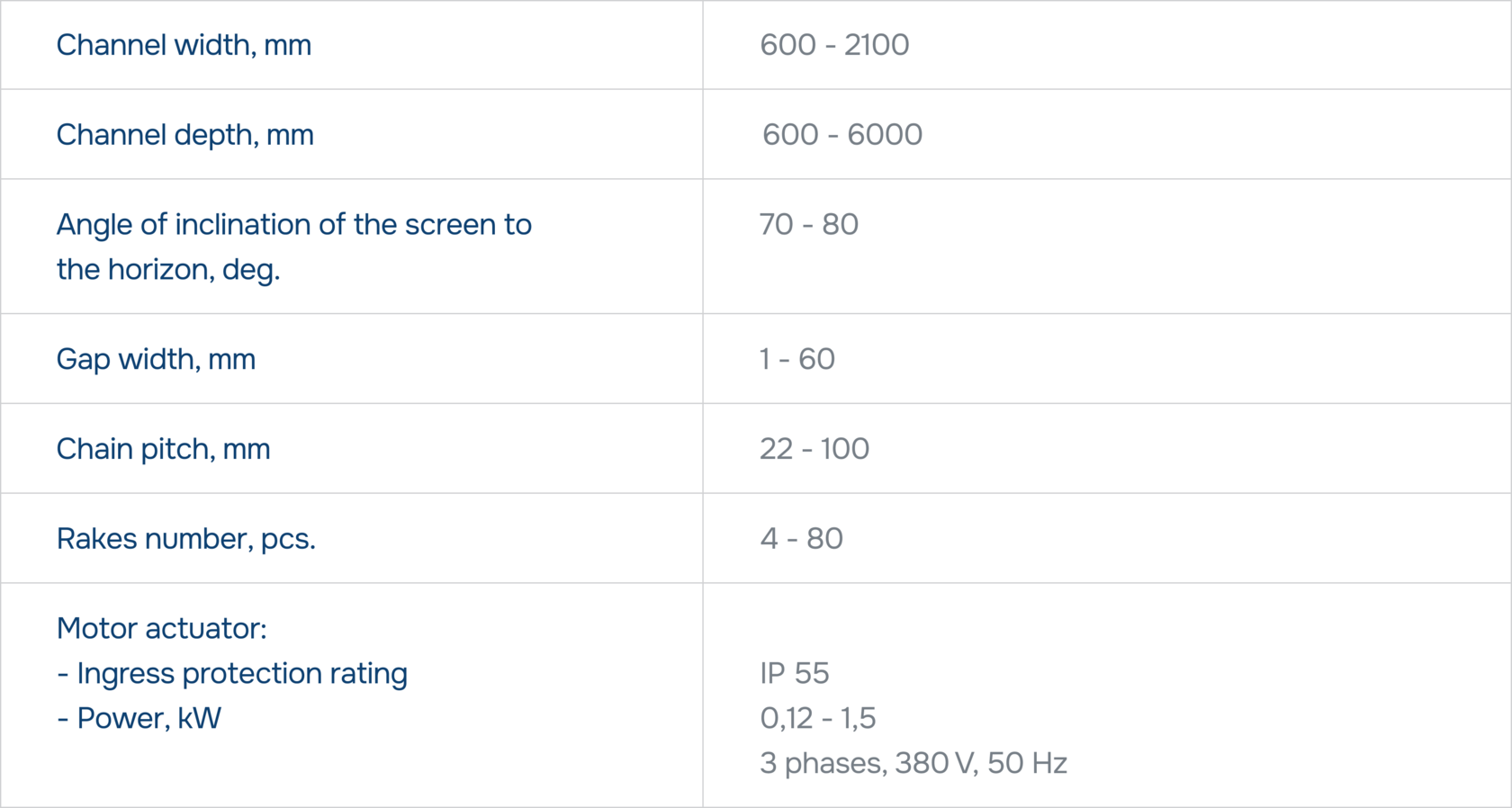

Technical characteristics