Scope of application:

- Sewage treatment plants of domestic and household wastewater;

- Local treatment facilities of industrial wastewater;

- Storm and surface wastewater treatment systems.

Working principle

The process is based on the density difference between water and mineral particles. Heavy mineral particles settle to the bottom of the sand trap, while lighter organic matter is directed to further treatment stages.The sand trap is a cone-shaped tank with an inclined conveyor of deposited sand. The upper flow area of the tank is approached by inlet and outlet pipes of waste water. Inside the tank a stirring device driven by a gear motor is mounted vertically. Another gearmotor drives the sand conveyor screw.

The sand conveyor is installed at an angle of 35° and is a fixed housing made of sections with a rotating screw inside. The circular cross-section of the housing is protected on the inside against abrasion by wear-resistant inserts. The casing sections are connected to each other by flange connections.

Wastewater enters the flow area of the cone-shaped tank and moves in a circle along its walls due to the movement of the agitating device. The sand slides down the walls of the cone-shaped tank. It accumulates in the lower part of the container, from where it is conveyed by a screw conveyor to the unloading unit and discharged into a storage tank or onto a conveyor.

Advantages of Tangential Grit Chamber:

- Compactness

- Ease of operation

- Productivity

- Functionality

- Reliability

What do we offer?

- The use of reinforced auger spirals;

- Precision manufacturing and engineering to ensure high durability;

- Precisely designed vessel geometry to maximize sand settling efficiency;

- Agitator to provide the agitation intensity required to effectively extract mineral impurities and prevent the settling of organic contaminants;

- Adjustable supports to level the unevenness of the surface provided for installation of the equipment;

- Circular spillway for optimal level maintenance in the sand trap;

- Ergonomic quick-release inspection covers;

- Easy assembly/disassembly;

- Main operating components are easily accessible for maintenance;

- Compact and hermetically sealed design.

Process automation is an integral feature of the equipment:

- Various modes of operation and control of the equipment;

- It is possible to organize the transfer of data on the state of the equipment to the top-level control system using standard communication protocols;

- Convenient and intuitive setting of operating modes from the operator panel.

Equipment protection:

- Equipping electric drives (stirrer and conveyor) with protection and start-up electrical equipment;

- Device signaling normal operation of the equipment and emergency situations;

- Possibility to reverse the screw (reverse) to eliminate possible jamming.

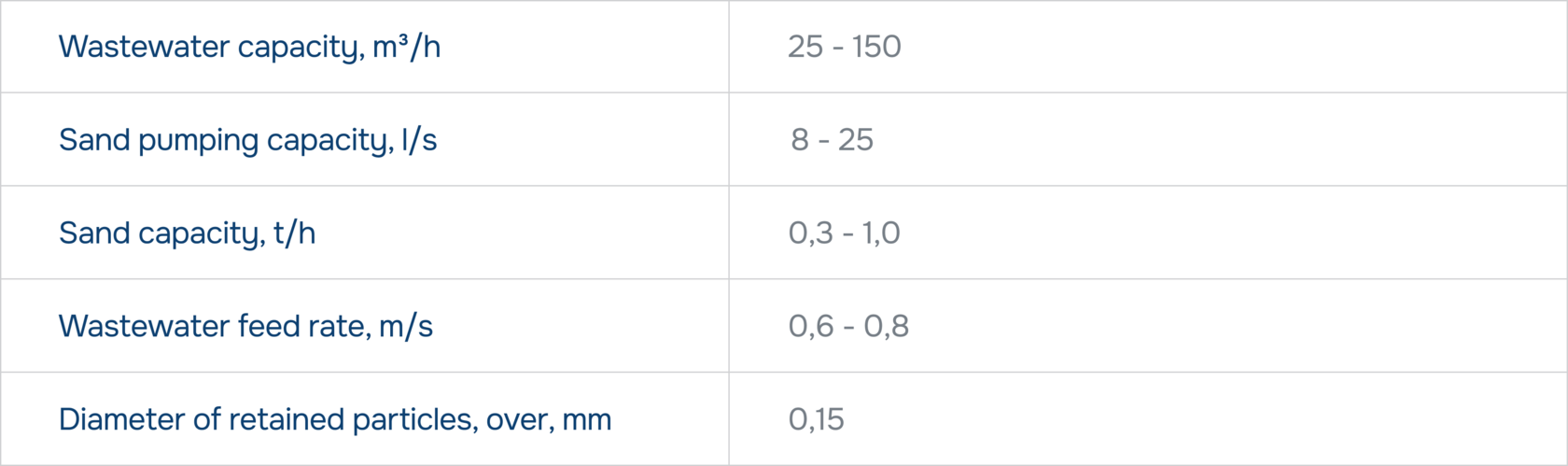

Technical characteristics